Motion Control Application – Truck Wheel Buffing Machines

The Application –

Motion Control – Polishing Aluminum Truck Wheels is done with a polishing machine that has a 36″ vertical stroke indexer, having a 2500 pound load moving @ 4″ per second. The polishing media is like toothpaste with glass in it. It is extremely abrasive, and sticky/tacky.

The Problem –

The industrial buffing system is chewing-up motion control linear ball bearings and spitting them out every 2 weeks! This is the situation one of customers found themselves in while for years accepting lost production and costly maintenance shutdowns. When LM76 got a call from a proactive new maintenance manager, we were eager to try a scraper seal design we had recently had success with on another application.

Originally, these systems came with protective bellows which helped keep polishing media from contaminating the 2″ linear ball bearing pillow blocks. According to our maintenance manager, once a bellow was damaged, it was removed and thrown away. Maintenance personnel so disliked having to take off and reinstall bellows that they mysteriously disappeared. Even with protective bellows, aluminum dust mixed with polishing media formed what one mechanic termed, “toothpaste with glass in it.”This abrasive “lapping compound”would stick to shafting, dry and semi-harden. As a bearing rolled along, polishing media would penetrate it’s seals “sliming” balls and clogging ball tracks. This would quickly lead to bearing failure and shaft brinneling (grooving). Needless to mention, routinely replacing linear ball bearings and more costly shafting was too much for the new maintenance manager who called LM76 for help.

The Solution –

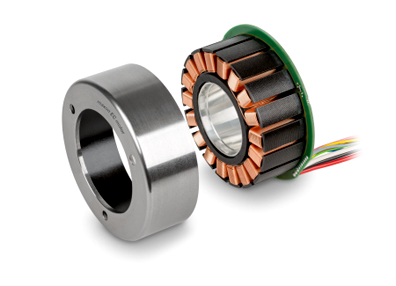

For this application, we chose our motion control Black Racer Ceramic Coated Linear Bearing. This bearing is extremely tough, is of one piece construction (no mechanical components, no catastrophic failure mode or shaft grooving) and has the longest life test we know of on record. Like linear ball bearings, Black Racer requires lubrication.

John Tarbell (President of LM76), specified a zero clearance beryllium copper scraper seal. Beryllium copper is exceptionally ridgid, extremely hard and wear resistant. The Beryllium copper would trap lubricant and distribute it as a fine, uniform film on the shaft. This film reduces friction, disperses heat and wets shafting. The wetted shaft surface forms a barrier between media and steel – keeping polishing media from cleating into disparities on the shaft (remaining peaks and valleys). Tarbel, said, “A Zamboni doesn’t lay down an inch of ice, it fills in the skate marks.” When the scraper travels on the shaft, it easily lifts the media and moves it along to the end of the stroke. Unlike linear ball bearings, Black Racer has no balls so some residual “slime” is easily accommodated. (Seen below, the beryllium scraper seal is captured between the bearing counter-bored face and the machined steel end cap.) Admittedly, a heavy interference fit dramatically raised system friction but was mitigated because the system is hydraulically driven – driving force is not an issue.

Staying within the form factor of the original OEM design–standard roundway pillow block and shafting–we chose our direct drop-in 2″ closed pillow block and Black Racer Ceramic Coated bearing coupled with our 2″, Class L Rc60 Case Hardened Shafting. Tarbell then designed a steel end cap retainer ring that pinned the beryllium scraper seal against the bearing face.

Note: The bearing leading and trailing faces have machined counter-bores to locate and capture the back of the scraper seal. To keep the retainer ring secured to the pillow block, set screws were positioned on both sides and driven into a slot machined into the OD surface.

To follow the NEW Series from LM76, THE ENGINEERING EDGE! and learn about interesting Outside-of-the-Box solutions developed by LM76 to solve some interesting linear motion problems! CLICK HERE

About LM76

Founded in 1976, LM76 has been a leading designer/manufacturer of linear bearings, slides and linear motion systems. LM76 is renowned for its industry leading Minuteman PTFE Composite linear bearings. LM76 is a leading supplier of precision linear shafting: RC60, 300 Series Stainless Steel, and ceramic-coated aluminum shafting. LM76 also offers several FDA/USDA compliant linear bearings and slides for the food processing, pharmaceutical, medical, and packaging industries.

For additional information contact Mike Quinn at: LM76, 140 Industrial Dr., E. Longmeadow, MA 01028; Telephone: 413-525-4166, Fax: 413-525-3735 or E-Mail: mquinn@lm76.com or visit the website at http://www.lm76.com

And say, “I saw it on MotionShop.com, “The Motion Control Home Page.”

See this and other Motion Control Components from LM76 featured on:

The LM76 Blog

LM76 Catalogs

http://MotionShop.com

http://LinearMotionBlogger.com

http://AllMotionBlogger.com

http://Automation-Blogger.com

http://MotionControlBlogger.com

http://motioncontrolBuyersGuide.com

http://MotionControlWeb.com

http://MotionShop.net

http://Catalogs-MotionControl.com